Mastek Intelligent Packing Machinery (Suzhou) Co., Ltd

- +86 512 8781 7868

- export@mastekpack.com

Mastek Intelligent Packing Machinery (Suzhou) Co., Ltd

In modern warehousing and logistics, securing pallets is critical to ensure that goods remain stable during transport and storage. Pallet strapping machines have become indispensable for manufacturers, distributors, and logistics providers looking to improve safety, efficiency, and cost control. However, one important decision businesses must make is whether to use a horizontal pallet strapping machine or a vertical pallet strapping machine.

As a trusted packaging solutions provider, Mastek offers advanced models in both categories, including the MK300 Vertical Pallet Strapping Machine and the MK600 Horizontal Pallet Strapping Machine. This article will explore the differences, advantages, and best-fit applications of each type to help you decide which solution suits your operation.

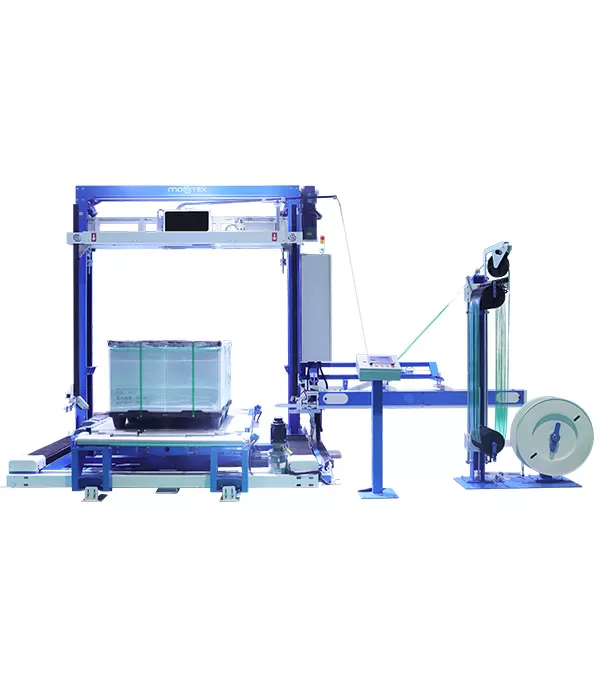

A vertical pallet strapping machine applies straps from top to bottom, securing the load vertically. The machine typically straps the palletized goods by compressing the load and applying vertical tension around the sides.

The Mastek MK300 Vertical Pallet Strapping Machine is designed to deliver fast, reliable, and consistent vertical strapping. It works well with stable pallet loads and is ideal for industries that frequently ship uniform products.

Provides strong vertical compression, keeping goods tightly secured.

Suitable for stable loads with uniform shapes and dimensions.

Efficient for industries with standardized packaging, such as beverages, paper products, or boxed goods.

Enhances stability during vertical stacking in warehouses.

Vertical strapping machines are commonly used in food and beverage, printing, cartons, and logistics where pallets are uniform and require consistent tension.

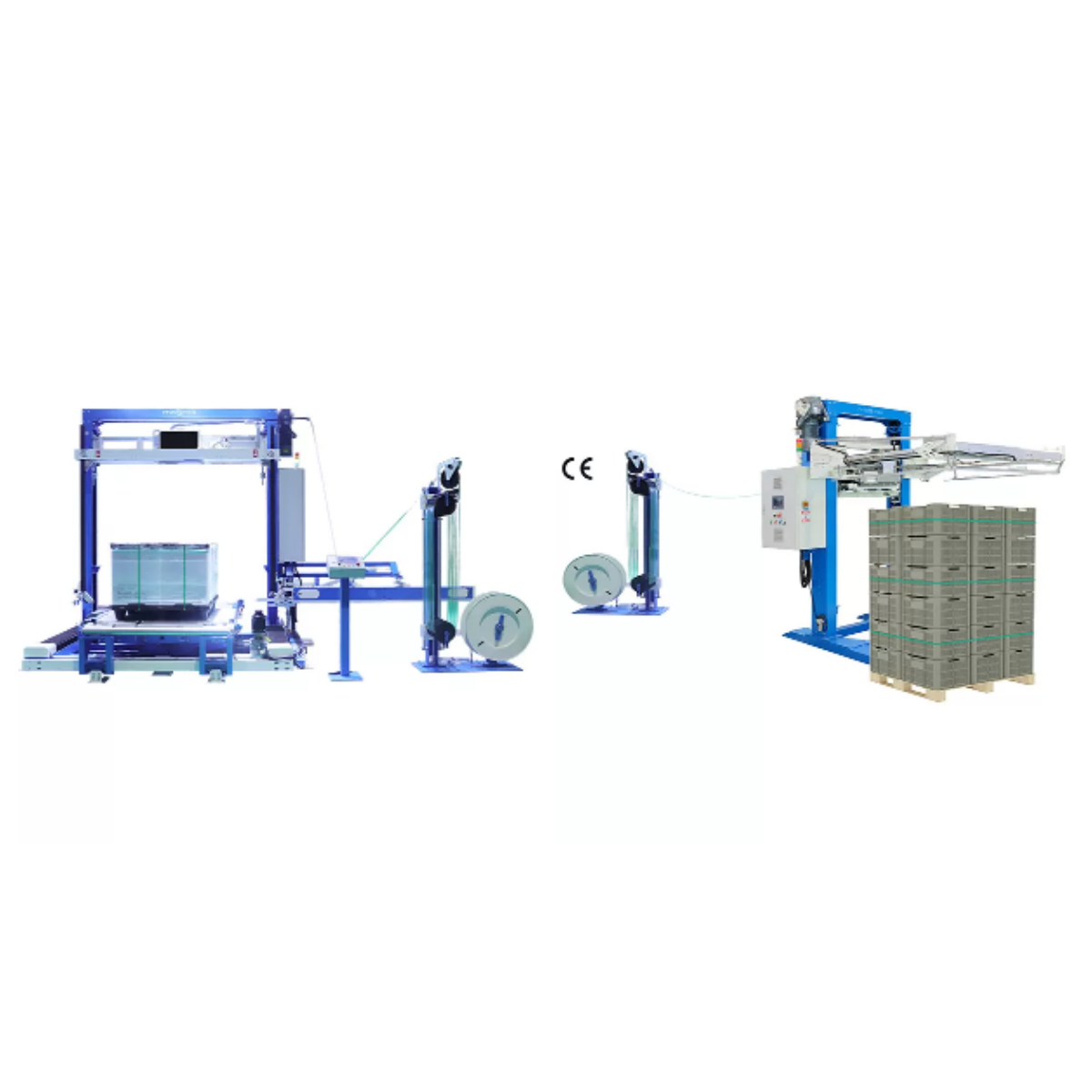

A horizontal pallet strapping machine applies straps across the pallet load, securing goods from side to side. Unlike vertical machines, they can strap pallets at multiple heights, making them highly adaptable for securing irregularly shaped or uneven loads.

The Mastek MK600 Horizontal Pallet Strapping Machine is built for versatility, allowing multiple strap positions along the pallet height. This ensures stability even for loads that are not uniform.

Offers adjustable strap positions at different heights.

Ideal for unstable, irregular, or fragile pallet loads.

Prevents shifting of goods during horizontal movement in transport.

Reduces risk of damage when vertical compression is not suitable.

Horizontal machines are widely used in building materials, furniture, logistics, construction products, and fragile goods packaging, where load sizes and shapes vary.

| Feature | Vertical Pallet Strapping | Horizontal Pallet Strapping |

|---|---|---|

| Strap Direction | Top-to-bottom around pallet sides | Side-to-side across the load |

| Best for | Stable, uniform pallet loads | Irregular, uneven, or fragile loads |

| Flexibility | Limited to vertical compression | Multiple adjustable strap heights |

| Speed | Very fast for consistent pallets | Slightly slower but more versatile |

| Industries | Beverage, food, carton, printing | Building materials, furniture, logistics |

When deciding between horizontal and vertical pallet strapping machines, consider these factors:

Load Stability – If your pallets are stable and uniform, a vertical strapping machine like the MK300 is more efficient. If your loads are irregular, a horizontal machine like the MK600 provides better security.

Industry Type – Logistics involving fragile or construction products may need horizontal strapping, while industries with uniform cartons can rely on vertical strapping.

Future Scalability – Horizontal machines offer more flexibility if you anticipate handling different pallet shapes in the future.

Operational Speed – Vertical machines are usually faster, making them ideal for high-throughput environments.

Mastek has a proven track record of delivering reliable and high-performance strapping machines that meet the diverse needs of global businesses. The MK300 vertical model and the MK600 horizontal model are both engineered with advanced technology, user-friendly operation, and durable design to withstand heavy industrial use.

By choosing Mastek strapping solutions, businesses can:

Improve packaging efficiency.

Enhance safety and load security.

Reduce labor costs and operational downtime.

Ensure adaptability for different industries and packaging requirements.

The choice between horizontal and vertical pallet strapping machines depends on your operation’s unique needs. If your business deals with consistent and stable loads, the Mastek MK300 Vertical Pallet Strapping Machine is an excellent fit. On the other hand, if your goods vary in shape, size, or fragility, the Mastek MK600 Horizontal Pallet Strapping Machine offers unmatched flexibility and security.

By investing in the right machine, you not only improve packaging efficiency but also strengthen your supply chain performance. With Mastek’s expertise and product range, you can find the strapping solution that fits your operation today and supports your growth tomorrow.